Human Resources

GDXL has 300 skillful employees working for processing.

60% employees have been working in GDXL over 5 years.

27% employees have been working in GDXL over 10 years.

6% employees have been working in GDXL over 15 years.

35% employees have been holding a diploma or a higher degree.

60% employees have been working in GDXL over 5 years.

27% employees have been working in GDXL over 10 years.

6% employees have been working in GDXL over 15 years.

35% employees have been holding a diploma or a higher degree.

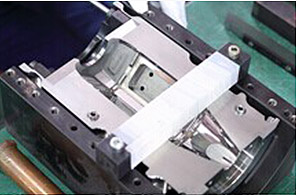

Processing Equipment

Use of the international

first-class high-precision processing equipment, more than 85% of the production processing is using automatic CNC processing equipments.

| Japanese horizontal machining equipment |

| Swiss high-precision grinding equipment |

| Swiss EDM machine |

| Swiss WEDM-LS machine |

| USA CNC lathing equipment |

| Japanese milling equipment |

| Swiss grilling equipment |

| Vacuum heat treatment furnace |

| German 5 axial machining equipment |

| German vertical machining equipment |

Production Management

GDXL dedicates pursuing high-grade management and promoting automatic manufacturing workshop as a goal; aiming to improve our data management, machine operation, products efficiency, quality, safety, and cost saving etc.

Resources System

GDXL uses PLM and ERP system to manage and arrange our daily datum, documents, resource distribution, etc.

Quality Control system

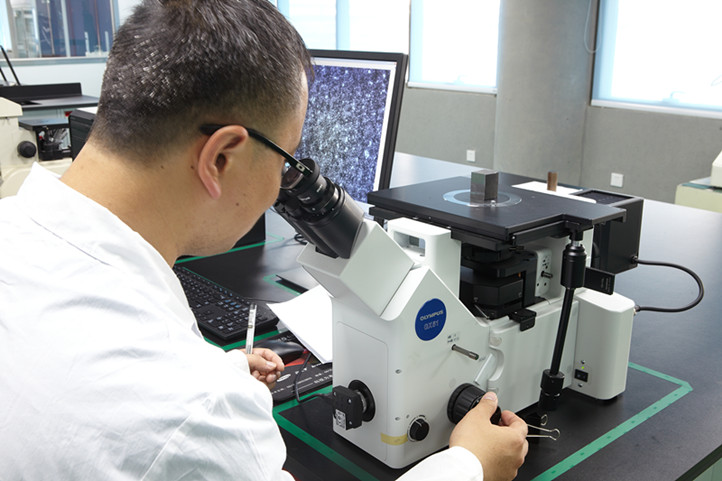

GDXL has a quality control department to oversee all inspection procedure that makes sure every single component in high quality before delivery to our customers.

Inspection Facilities

GDXL inspection centre has over 60 high precision inspection instruments and R&D instruments which are all over US$ 2,000,000.

Production

Lead-time

Schematic diagram of mold testing and product testing

flow chart

flow chart

| Cold-fill blow mold: less than 200 cavities, 25 days |

| HR blow mold: less than 100 cavities, 30 days |

| Preform mold: 72 cavities, 45 days |

| Preform mold: 96 cavities, 50 days |

| Closure mold: 60 days |

| Hot runner: 70 days |

Semi-finished

Product Inventory

Blow mold: 8,000 – 10,000 cavities standardized semi-finished products

Peform mold: 40 sets 32 – 144 cavities standardized semi-finished products

Capacity

Blow mold:30,000 cavities per year

Preform mold: 20,000 cavities per year

Closure mold: 3,000 cavities per year.

Preform mold: 20,000 cavities per year

Closure mold: 3,000 cavities per year.

中文

中文 English

English